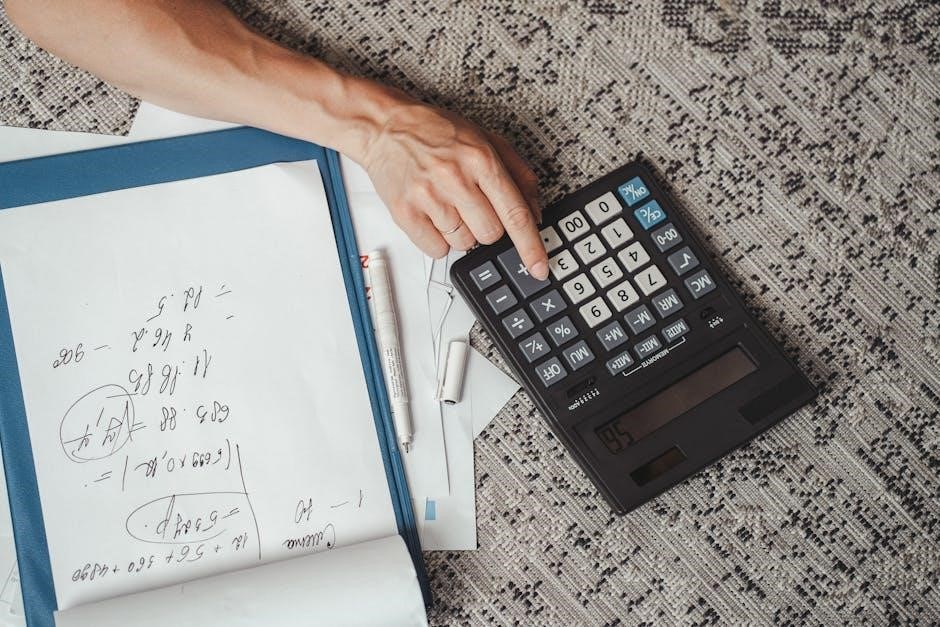

Manual tube bending calculations involve determining feasibility based on curvature radius, wall thickness, and the K-factor, crucial for accurate results.

Importance of Accurate Calculations

Accurate calculations are paramount in manual tube bending to prevent material failure, ensure dimensional correctness, and minimize costly rework. Incorrect estimations of bend allowance or minimum radius can lead to tube collapse, wrinkling, or excessive springback. Precise determination of the K-factor, reflecting material properties, is also vital.

Furthermore, understanding deflection using formulas like PL3/48EI helps predict deformation under force, avoiding plastic deformation beyond acceptable limits. Proper calculations guarantee the final bent tube meets design specifications, maintaining structural integrity and functionality. Utilizing manufacturer’s specifications and tolerance charts further refines accuracy, leading to successful bending outcomes.

Overview of Bending Principles

Manual tube bending relies on understanding how material deforms under stress. The neutral axis, an imaginary line through the tube’s center, dictates curvature. Bending isn’t a simple arc; it involves stretching on the outer radius and compression on the inner. Calculations must account for this uneven stress distribution.

Techniques often involve intuitive, experience-based estimations, alongside formulas. Achieving 90-degree bends requires precise alignment, utilizing markings on both the tube and bending tool. Successful bending depends on controlled force application and understanding how the material responds, avoiding exceeding plastic deformation limits and ensuring a smooth, accurate bend.

Key Parameters in Tube Bending

Essential parameters include tube diameter, wall thickness, radius of curvature, bend radius, and the material’s K-factor, all impacting bending feasibility and accuracy.

Tube Diameter and Wall Thickness

Tube diameter and wall thickness are fundamental parameters in manual bending calculations. The diameter directly influences the required bending force and the resulting radius of curvature. Thicker walls generally require more force but offer greater resistance to collapse during bending. Conversely, thinner walls are easier to bend but are more susceptible to deformation or wrinkling.

Accurate measurement of both parameters is critical; even slight variations can significantly affect the final bend geometry. Manufacturers often provide specifications for minimum bend radii based on these dimensions. Understanding the relationship between diameter, wall thickness, and bendability is essential for successful manual tube bending, ensuring structural integrity and dimensional accuracy.

Radius of Curvature (R) and Bend Radius

Radius of curvature (R) defines the tightness of a bend, measured to the tube’s center line. The bend radius is crucial for determining if a tube can be bent without failure. A smaller radius demands more force and increases the risk of collapse, especially with thinner walls. The neutral axis, running through the tube’s center, is key to understanding curvature.

Calculations involving R are directly linked to tube diameter and wall thickness. Determining the appropriate bend radius ensures the final product meets design specifications and maintains structural integrity. Manufacturers often provide charts or calculators to aid in selecting a suitable radius based on material properties and tube dimensions.

The K-Factor: Material and Bend Properties

The K-factor represents a material’s resistance to bending and is vital for calculating bend allowance and minimum bend radius. It accounts for how a specific material behaves during deformation, differing between steel, aluminum, and other alloys. This factor considers both the material’s properties and the bending process itself.

A higher K-factor indicates greater resistance to bending, requiring more force. Accurate K-factor determination is essential for preventing tube collapse or wrinkling. It’s directly related to the radius of curvature, tube thickness, and material type, influencing the viability of achieving a desired bend. Utilizing the correct K-factor ensures accurate calculations and successful manual bending.

Calculating Bend Allowance

Bend allowance calculations depend on tube wall thickness, diameter, and curvature radius, aiding in determining the correct tube length for desired bends.

Understanding Bend Allowance

Bend allowance represents the length of material needed to form a bend without stretching or compressing the tube. It’s a critical factor in achieving accurate bends, preventing gaps or overlaps in fabricated assemblies. Essentially, it compensates for the material that’s “consumed” during the bending process.

Without proper bend allowance calculation, the final bent tube will likely deviate from the intended dimensions. This is because the inner portion of the bend compresses while the outer portion stretches. The allowance accounts for this material redistribution. Accurate determination relies on understanding the tube’s geometry and material properties, ensuring a precise fit within the overall design.

Formula for Bend Allowance Calculation

The fundamental formula for calculating bend allowance is: Bend Allowance = (π/180) * Bend Angle * Average Radius. The average radius is determined as (Outside Radius + Inside Radius) / 2, representing the neutral axis where material isn’t significantly stretched or compressed.

However, this is a simplified version. More precise calculations incorporate the K-factor, accounting for material properties and bend severity. Manufacturers often provide bend allowance charts or calculators tailored to specific tube diameters and wall thicknesses, streamlining the process. Utilizing these resources ensures greater accuracy, minimizing errors in manual bending operations and achieving desired results.

Impact of Material on Bend Allowance

Material properties significantly influence bend allowance calculations. Different metals exhibit varying degrees of elasticity and plasticity, affecting how they respond to bending forces. The K-factor, representing material’s bendability, directly impacts the required allowance.

For instance, softer metals like aluminum necessitate larger allowances due to increased springback, while harder steels require less. Tube wall thickness also plays a crucial role; thinner walls are more prone to deformation. Accurate material identification and corresponding K-factor selection are paramount for precise manual bending, preventing inaccuracies and ensuring the final product meets specifications;

Determining Minimum Bend Radius

Minimum bend radius prevents tube collapse or wrinkling, relying on tube properties and manufacturer specs for safe, successful manual bending operations.

Avoiding Tube Collapse and Wrinkling

Preventing tube collapse and wrinkling during manual bending is paramount for maintaining structural integrity. The minimum bend radius directly influences this; exceeding it risks deformation. Calculations must consider the tube’s diameter, wall thickness, and material properties. A smaller radius increases the likelihood of buckling, especially with thinner walls.

Understanding the relationship between these factors is crucial. Manufacturers often provide specifications or bend radius charts to guide users. These resources detail acceptable radii for specific materials and dimensions. Ignoring these guidelines can lead to compromised tube strength and potential failure. Careful calculation and adherence to recommended radii are essential for successful, safe manual bending.

Relationship Between Tube Properties and Minimum Bend Radius

The minimum bend radius is intrinsically linked to a tube’s material and dimensions. Tubes with larger diameters and thicker walls generally tolerate smaller bend radii. Conversely, thinner-walled tubes and those made from less ductile materials require larger radii to prevent collapse or wrinkling. Material ductility plays a significant role; more malleable materials can withstand tighter bends.

The calculation considers the tube’s outer diameter (OD) and wall thickness. A common guideline suggests a minimum radius equal to a multiple of the OD, varying based on material. Understanding these relationships is vital for accurate manual bending calculations, ensuring the final product maintains its structural integrity and intended functionality.

Using Manufacturer’s Specifications

Relying on manufacturer’s specifications is paramount for precise manual tube bending. These documents provide crucial data, including recommended minimum bend radii, allowable tolerances, and material-specific K-factors. Many manufacturers offer bend tolerance charts or calculators, simplifying the process of determining the correct tube length before bending.

These specifications account for the specific alloy composition and manufacturing processes, offering a more accurate assessment than generic formulas alone. Ignoring these guidelines can lead to defects like ovality, wrinkling, or even failure. Always prioritize the manufacturer’s recommendations to ensure a successful and structurally sound bend.

Stress and Deformation Analysis

Analyzing stress and deformation utilizes formulas like PL3/48EI to calculate deflection, assessing plastic deformation limits and allowable force during manual bending.

The PL3/48EI Formula for Deflection

The PL3/48EI formula is a cornerstone of stress analysis in tube bending, predicting the amount of deflection under an applied load. Here, ‘P’ represents the applied force, ‘L’ is the length of the tube span, ‘E’ denotes the material’s modulus of elasticity, and ‘I’ signifies the area moment of inertia. This equation helps determine if deformation will remain elastic or transition into plastic deformation.

If the calculated deflection exceeds 250 times the support point, plastic deformation is likely. Understanding this threshold is vital for manual bending, as exceeding it can lead to permanent shape changes or even tube failure. By rearranging the formula, one can solve for the allowable force (‘F’) to maintain elastic behavior, ensuring structural integrity during the bending process.

Plastic Deformation Limits

Plastic deformation in tube bending occurs when the applied stress exceeds the material’s yield strength, resulting in permanent changes to the tube’s shape. While some plastic deformation is inherent in bending, exceeding defined limits compromises structural integrity and dimensional accuracy. The PL3/48EI formula assists in identifying the point where plastic deformation becomes significant.

Specifically, if deflection surpasses 250 times the support point, plastic deformation is highly probable. Manual bending requires careful control to stay within these limits. Understanding the material’s properties – its yield strength and modulus of elasticity – is crucial for predicting and preventing unwanted plastic deformation, ensuring the final bent tube meets required specifications and maintains its intended function.

Calculating Allowable Force

Allowable force during manual tube bending is a critical parameter to prevent material failure or excessive deformation. Utilizing the PL3/48EI formula, one can rearrange it to solve for ‘f’ (force). This calculation determines the maximum force that can be applied without inducing unacceptable plastic deformation, where deflection exceeds 250 times the support point.

Accurate determination requires knowing the tube’s length (P), material properties (E – modulus of elasticity, I – moment of inertia), and the desired deflection. Carefully calculating and adhering to this allowable force ensures controlled bending, preserving the tube’s structural integrity and dimensional accuracy throughout the manual bending process.

Practical Considerations for Manual Bending

Manual bending requires proper tools, alignment marking, and understanding techniques for achieving precise 90-degree bends, relying on experience and intuition.

Using Bending Tools and Dies

Selecting the correct bending tool and die is paramount for successful manual tube bending. Various manufacturers provide bending tools, often including tolerance charts to aid in determining the appropriate tube length needed for desired bends. These tools utilize dies matched to the tube’s outer diameter, ensuring a smooth, controlled bend.

The alignment of the tube within the die is critical; proper positioning prevents deformation and ensures accuracy. Manual benders often feature markings to align the tube with the bending point, facilitating consistent results. Understanding the tool’s mechanics – how it applies force and controls the bending radius – is essential for achieving the intended shape. Careful consideration of the material and tube dimensions will dictate the appropriate tool and die selection for optimal performance.

Marking and Alignment Techniques

Precise marking and alignment are fundamental to accurate manual tube bending. Begin by carefully marking the desired bend location on the tube, referencing calculations for bend allowance and springback. Align this mark with the designated point on the bending tool or die, often indicated by a star or other reference marker.

For 90-degree bends, as seen in some techniques, aligning the starting point of the bender towards the end of the tube is crucial, remembering the direction is reversed from the previous angle. Consistent alignment ensures the bend occurs at the intended location, minimizing errors. Double-checking alignment before applying force is vital for achieving the desired geometry.

Techniques for 90-Degree Bends

Achieving precise 90-degree bends manually requires careful technique. Align the initial mark on the tube with the corresponding indicator on the bending tool, often a star marking. Initiate the bend, understanding that the direction will be opposite to that of previous angles.

Intuitive calculations, developed through experience, can aid in estimating the required force and bend point. Some practitioners employ mental calculations, relying on practiced estimations rather than strict formulas. Continuously monitor the bend’s progress, comparing it to the desired angle, and adjust as needed. Consistent pressure and controlled movement are key to a clean, accurate 90-degree bend.

Tolerance and Springback

Springback, the tube’s partial return to its original shape, necessitates overbending. Tolerance charts and calculators help determine the correct initial bend angle.

Understanding Springback in Tube Bending

Springback is an inherent phenomenon in tube bending, representing the elastic recovery of the material after the bending force is removed. It’s the partial return of the tube towards its original, unbent shape. This occurs because the material, while plastically deformed on the inner radius of the bend, retains some elastic memory.

Accurately accounting for springback is vital for achieving the desired final bend angle. Without compensation, the actual bend will fall short of the intended measurement. The degree of springback is influenced by several factors, including the material’s yield strength, the tube’s diameter-to-wall thickness ratio (D/t), and the bend radius. Higher yield strength materials and smaller bend radii generally exhibit greater springback. Understanding these influences is key to precise manual bending calculations.

Calculating and Compensating for Springback

Compensating for springback requires overbending the tube slightly during the initial bending process. The amount of overbend needed is determined through calculations or by referencing bend tolerance charts provided by tube manufacturers. These charts correlate material type, tube dimensions, and bend radius to estimate springback percentages.

A simplified approach involves experimentally determining the springback for a specific setup. Bend a sample tube, measure the actual angle, and calculate the difference from the target angle. This percentage can then be applied to subsequent bends. More complex calculations consider material properties and geometric factors. Accurate compensation ensures the final bent tube meets dimensional specifications, minimizing rework and material waste.

Bend Tolerance Charts and Calculators

Bend tolerance charts, often supplied by tube manufacturers, are essential tools for manual bending calculations. They provide pre-calculated allowances for springback and deformation, based on tube diameter, wall thickness, material type, and bend radius. These charts simplify the process, eliminating complex formulas for common bending scenarios.

Online calculators offer a more dynamic approach, allowing users to input specific parameters and receive customized tolerance values. These tools often incorporate material databases and advanced algorithms for increased accuracy. Utilizing these resources minimizes errors, ensures consistent results, and helps determine the correct tube length before bending, reducing material waste and improving overall efficiency.

No Responses